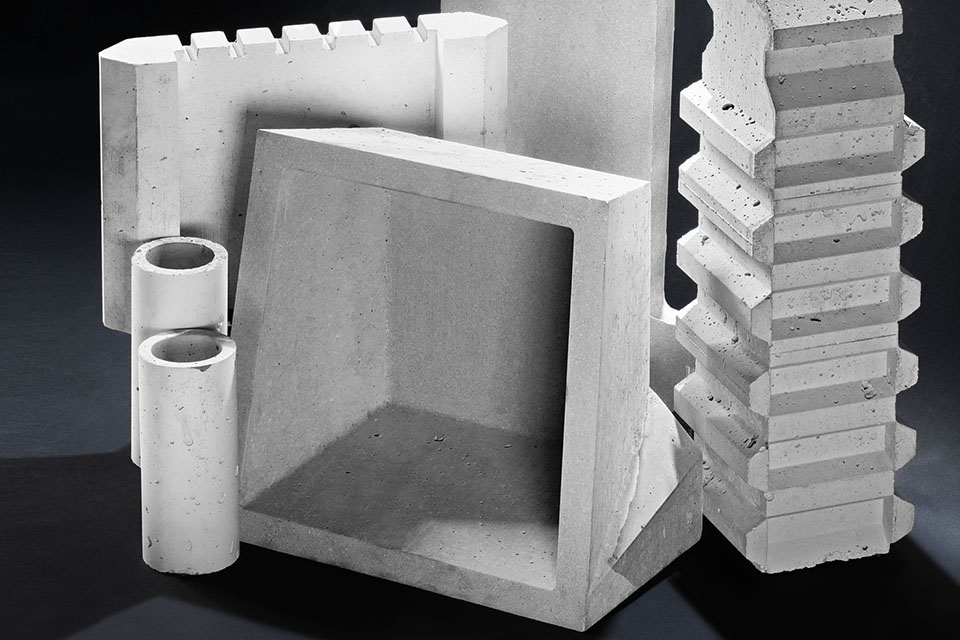

We offer HP, SHP and UHP grade graphite electrodes in diameter range 152-610 mm.

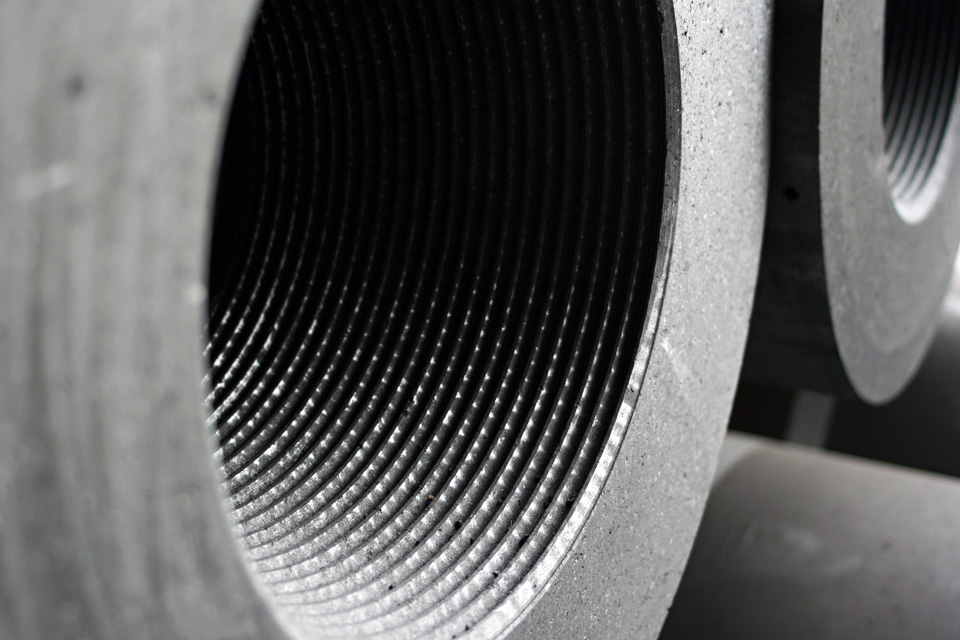

We produce graphite electrodes from semi-finished graphitised bars by machining for perfect geometry of the sockets and end surfaces. The manufacturing process includes measuring the internal parameters of electrodes including non-destructive ultrasonic measurement of the strength of electrodes and connecting nipples.

To enhance the performance and longevity of graphite electrodes, we have developed a technology that involves impregnating them with antioxidants.

This process includes filling the voids in the graphite structure with liquid antioxidants throughout the entire volume of the electrode using vacuum technology, followed by heat treatment during which the impregnate crystalizes in the graphite voids. This impregnation effectively protects electrodes from lateral burn-off while also increasing their mechanical strength and thermal conductivity. As a result, electrodes treated with this technology demonstrate a 10 – 25 % reduction in consumption compared to conventional graphite electrodes, significantly improving their efficiency and lifespan in industrial applications.

To ensure a timely and reliable just-in-time deliveries of graphite electrodes to our customers, we keep over 1000 tonnes of electrodes in stock at all times.

The machining, measuring and impregnating of graphite electrodes are certified according to ISO 9001.

-

graphite electrodes.pdf

317 kB

graphite electrodes.pdf

317 kB