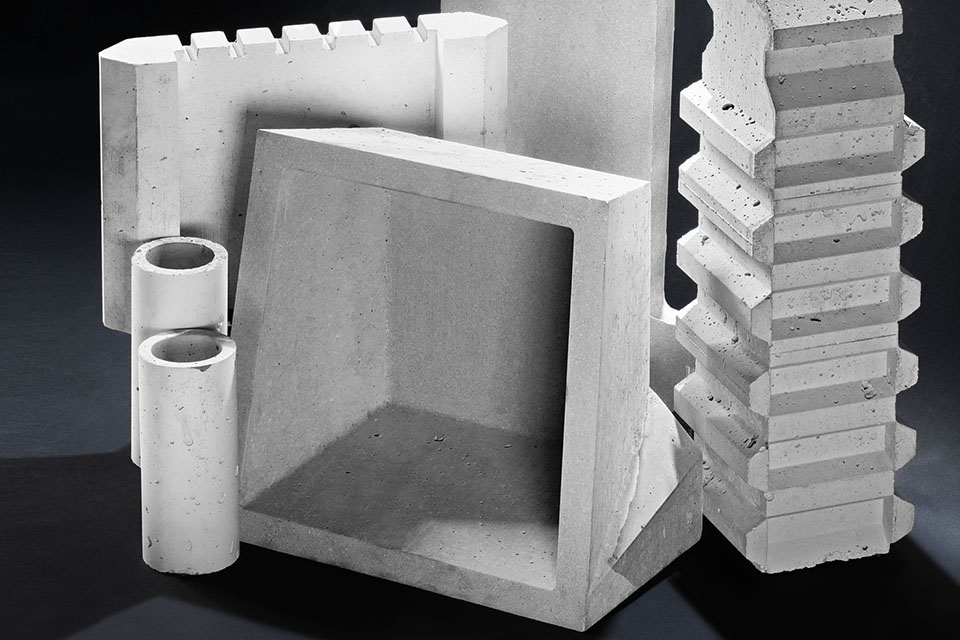

We produce graphite parts according to customer’s drawings, including providing the required quality of the graphite material.

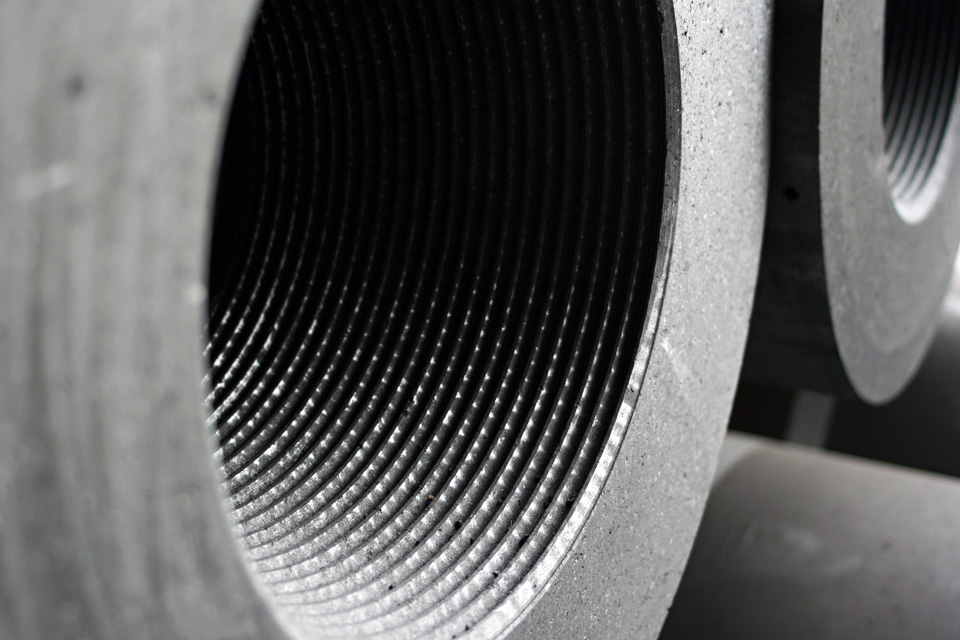

Our specialized graphite processing machining centre cuts, turns, mills, drills and grinds on modern CNC machine tools. We machine parts up to 1,270 x 610 x 720 mm (milling machine), or Ø 900 x 3,500 mm (lathe).

In addition to machining, we vacuum impregnate with antioxidants, which reduces burn-off and extends the service life of thermally exposed graphite parts.

Our standard products include degassing rotors for aluminium refining, crucibles, moulds, troughs, rods and tubes made of various types of extruded and isostatically pressed graphite.

Refining rotors made of graphite impregnated with antioxidants

JAP refining rotors are characterized by their long service life and high refining efficiency. We produce three basic rotor types - F2 (possible modifications F2A, F2B, F2L), G1 and J8.

The F2 series refining rotors, the design of which is patent pending, are suitable for the use together with refining salts in situations when a strong vortex needs to be created in the melt. They are manufactured in different variants and sizes according to customers' requirements (degree of vortex formation in the melt, etc.).

Refining rotors G1 have a universal use, but the vortex formation does not reach the level of the F2 series rotors.

Rotor J8 is suitable for refining without the use of refining salts. The rotor does not create a vortex in the melt.

Downloadable Content

-

Graphite products EN

1 MB

Graphite products EN

1 MB

-

JAP Rotors Leaflet

3 MB

JAP Rotors Leaflet

3 MB