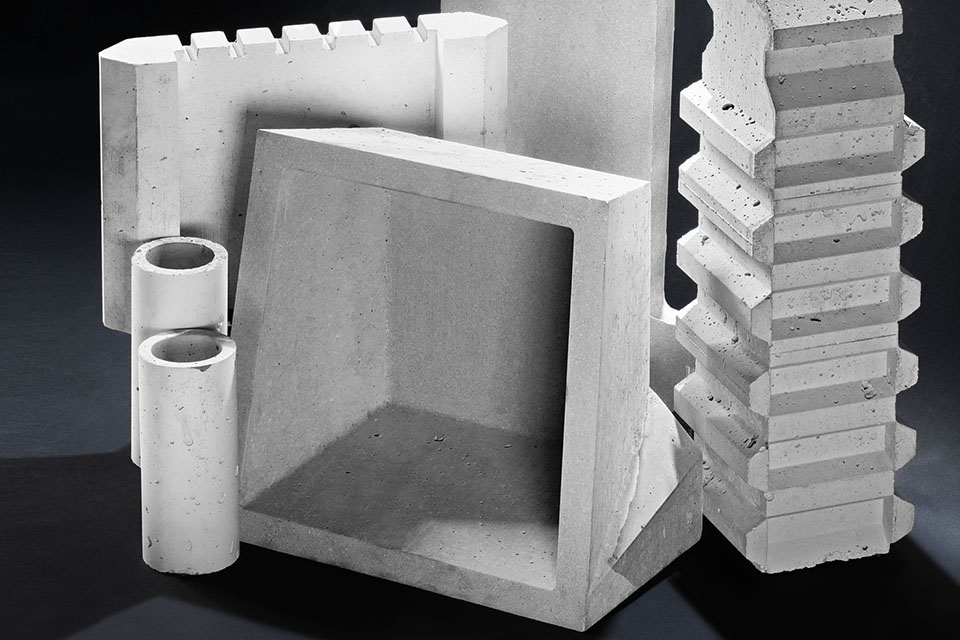

We produce the precast products based on our own recipes or from ready-made castables. Our own recipes have been enhanced based on our experience and the latest knowledge and practical expertise in the fields of heat treatment of metals, combustion of wood, wood waste, pellets, coal, or incineration of municipal and hazardous waste. The basic raw material base is burnt clay, high alumina abrasives, bauxite and high alumina cements. For the actual production - from the preparation of the mixtures, to vibrating, curing and tempering in an electric kiln - the latest technologies are used.

Precast refractory shapes are used by manufacturers of boilers, fireplaces and stoves for solid fuels, especially wood and wood pellets. If necessary, we are able to produce precast products with high resistance to alkali corrosion. We can also produce decorative refractory blocks with high aesthetic requirements that are used in stoves.

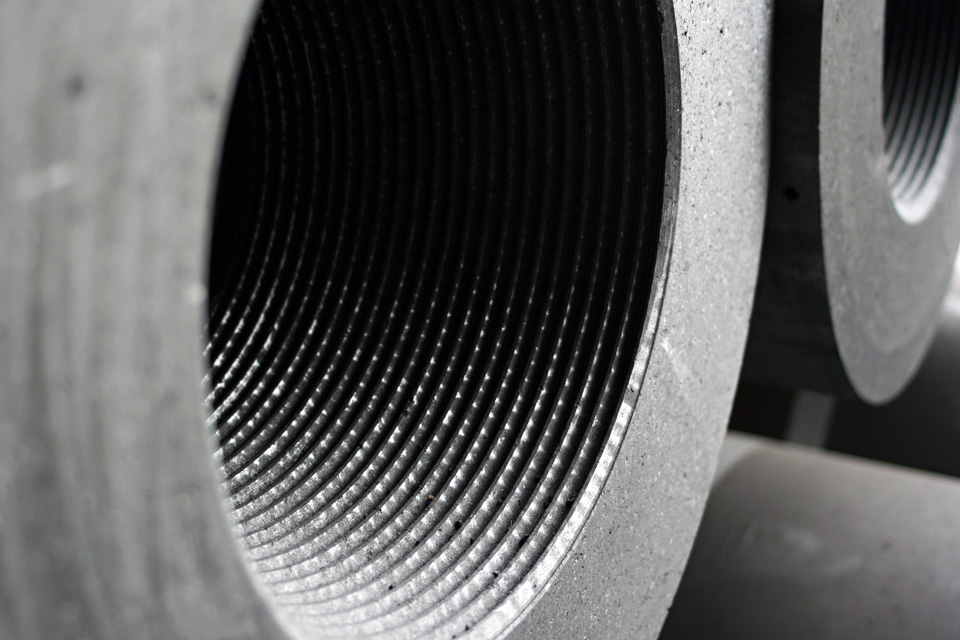

We also specialize in manufacturing of various prefabricated products for aluminium foundries. These include troughs, refining rotors and baffle plates, pouring funnels and so on.

For steel plants, we can produce tundish well blocks, turbostops and barriers (dam blocks) for controlling the flow of molten metal in a tundish, monolithic deltas of electric arc furnaces, or ladle purging plug well blocks.

Samples of our products: