Briquetting of powder materials

We operate two briquetting lines with a total capacity of up to 3,000 tons per month. The facility is mainly used for processing our own raw materials, but we also offer free capacity for briquetting powder materials provided by our customers. Our briquetting lines can process fines with grain size 0-8 mm. The briquettes can be composed of up to five different raw materials which are continually mixed with liquid binder prior to briquetting. The briquettes are oval, the standard size of briquettes is 55 x 50 x 40 mm. If necessary, the briquettes can be forced dried. The briquettes can be shipped as bulk or packed in big bags.

Our standard product range includes briquettes made of ferroalloy fines (FeSi, SiMn, FeMn), wollastonite, corundum, synthetic slag and other industrial by-products (dust, scales, undersized coke, anthracite, etc.). We can process a suitable combination of raw materials which are difficult to be used independently into briquettes that can replace expensive primary raw materials in various industrial processes.

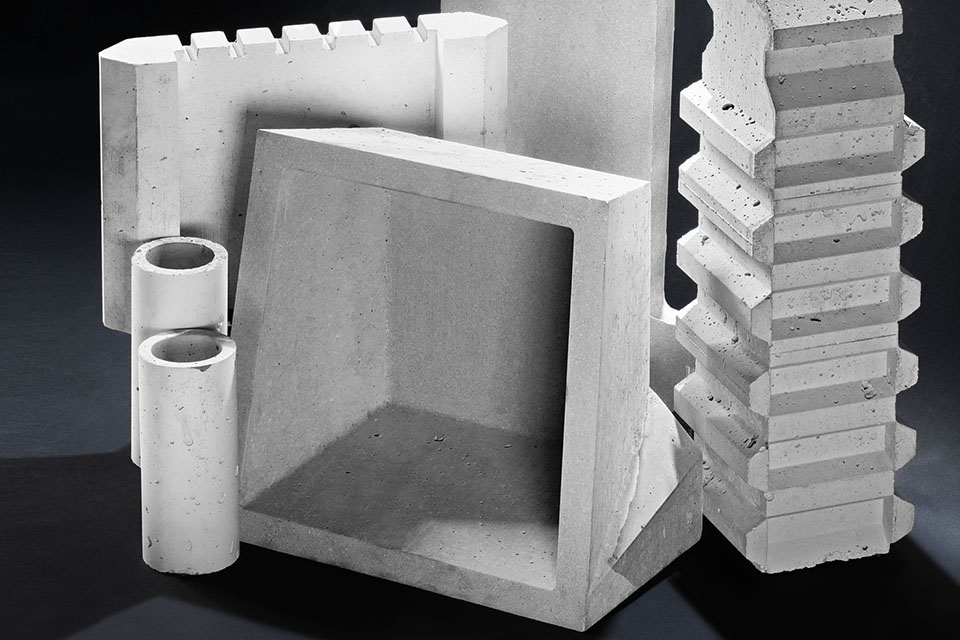

Custom production of graphite parts

We operate a specialized workshop for machining of graphite, equipped with saws, CNC lathes and CNC milling machines. We can turn graphite parts up to Ø 900 x 3,500 mm and up to 3,500 kg and mill graphite parts up to 1,270 x 610 x 720 mm and up to 1,200 kg.

Our standard product range includes degassing rotors for aluminium foundries, graphite rods, plates and blocks for processing non-ferrous metals and refractory materials, crucibles and moulds for casting precious metals, and other graphite products for non-ferrous metallurgy and chemical industry.

We offer custom machining of graphite parts according to customersᶦ requirements including graphite blocks and bars for their production.

We impregnate graphite parts with antioxidants and measure inner parameters of graphite (including non-destructive measurement of mechanical strength by ultrasound).

Repair of graphite electrodes

We repair damaged graphite electrodes for arc and ladle furnaces. We provide new connecting nipples and measure the internal parameters of graphite electrodes.

Unrepairable graphite electrodes, shavings and cuttings are purchased as raw material for production of carburizers.

Graphite waste recycling

We process a wide range of graphite and ceramic industrial waste. We buy all kind of graphite waste and arrange its transport to our plant.

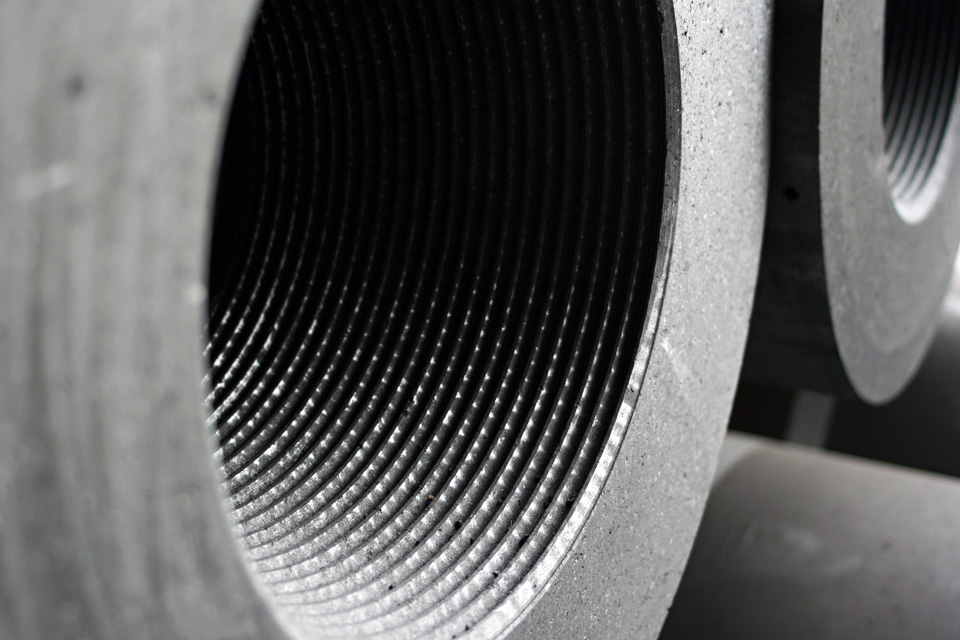

Repair of ladle sliding gate valves

We operate a production line for repair of ceramic plates of sliding gate valves for ladles. The restoration of sliding gate valves consists of drilling off the worn-out parts of ceramic plates and gluing in special ceramic inserts of the required casting diameter. We can also repair bottom plates with fixed welded sink cones. If the metal part of the cone is damaged, we weld on a new nozzle cone. Then, the drilled part of the nozzle is filled with refractory concrete. Forced drying in an electric furnace is followed by grinding the functional surfaces with size tolerance of 0.03 mm.

The service life of renovated ceramic plates is fully comparable to the service life of new plates. Depending on the degree of wear and the quality of the original ceramics slide plates, sliding gate valves can be refurbished several times. Cost effective repair of sliding gate valves represents a welcome opportunity for reduction of refractory cost in steel mills.